Steel fibres – how to specify?!

Every year in Australasia over 1m m3 of concrete is reinforced with steel fibres. These are supplied into a wide range of applications such as ground slabs, precast, shotcrete, water retaining structures, tunnel segments to name a few.

Ensuring the steel fibres are manufactured in a quality controlled environment should be seen as a minimum requirement for any steel fibre reinforced concrete (SFRC) specification. Just as AS/NZS 4671 Steel Reinforcing Materials is specified as a minimum requirement for mesh or bar.

How to specify

- Fibres should be manufactured in accordance with EN14889-1, system 1 for structural use or, ISO13270 Class A.

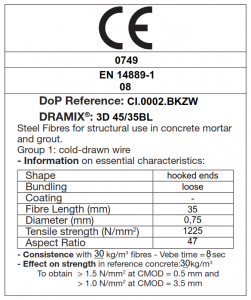

- A Declaration of Performance (DoP) should be supplied to the project engineer or interested party and will be used to check against the CE label attached to delivered pallets of fibre.

- Fibers without a DoP and corresponding CE label attached to delivered product do not comply.

(both these Standards have been cited in AS 5100.5 as a minimum requirement for steel fibres)

Of course the next important part of any specification is the required performance of the SFRC. This should either be specified in terms of residual flexural strength, toughness indices or fibre type and dosage if the tendered design is based on a specific fibre.

Depending on the application additional requirements for concrete quality control may be required; fibre batching process, checking fibre distribution, etc.

Please contact BOSFA if you require assistance with design and/or specification.

Background

EN14889-1 Steel Fibres. Definitions, specifications and conformity or, as it’s commonly referred to – ‘CE certification’, is a performance based manufacturing standard used by steel fibre producers. It sets out the level of quality control required for all the fibre characteristics that influence performance; length, diameter, aspect ratio, E modulus and tensile strength. Importantly, certification to this Standard is issued by a 3rd party.

There are two types of classification; system 1 for structural use and system 3 for non-structural use. Structural use is where the post crack residual strength values are used in design, this applies to almost all SFRC applications. Another requirement of this standard is that producers also need to declare the minimum fibre dosage required to reach a prescribed level of performance. This provides an independent means to compare the expected performance of fibre types produced by different manufactures.

What documents should be requested to ensure compliance?

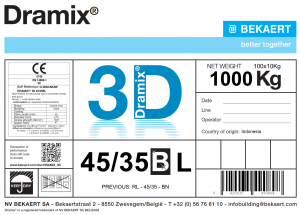

The fibre supplier should provide a current CE label (example shown below) and the DoP. This label is attached to every pallet (also shown below) of Dramix® supplied to the market and can be used as a QC check at the batching plant to ensure the specified fibre is being used.