BOSFA Fibres first for Tunnel Segments in Australia

Dramix Fibres used to reinforce the precast concrete segments for tunnel lining

GOLD COAST DESALINATION PLANT

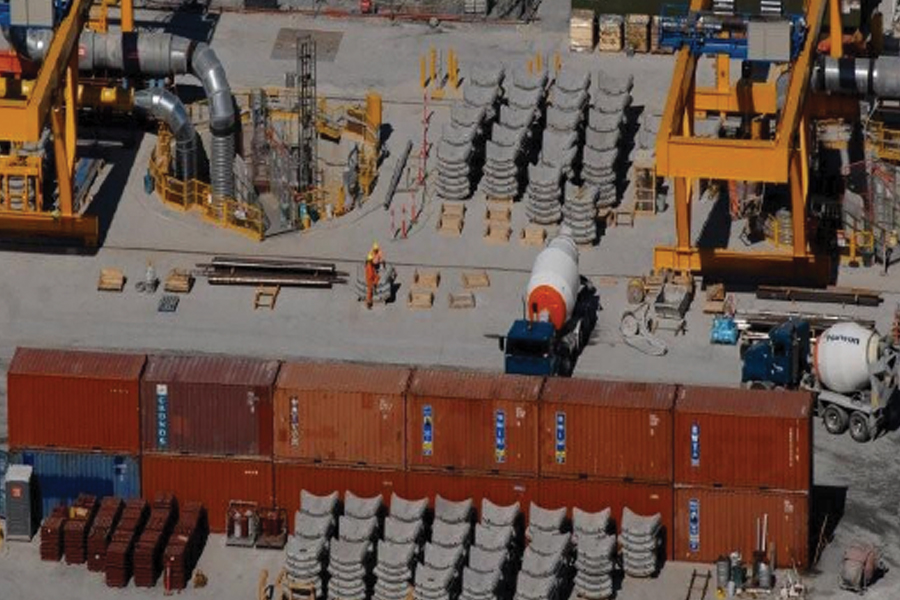

For the first time in Australia the significant advantages of using steel fibre reinforced concrete (SFRC) to manufacture precast segments for tunnel lining has been adopted for the Gold Coast Desalination Plant at Tugun. Owned by the Gold Coast City Council and the Queensland Government it is being built by the GCD Alliance made up of Veolia Water Australia, John Holland, Sinclair Knight Merz and Cardno.

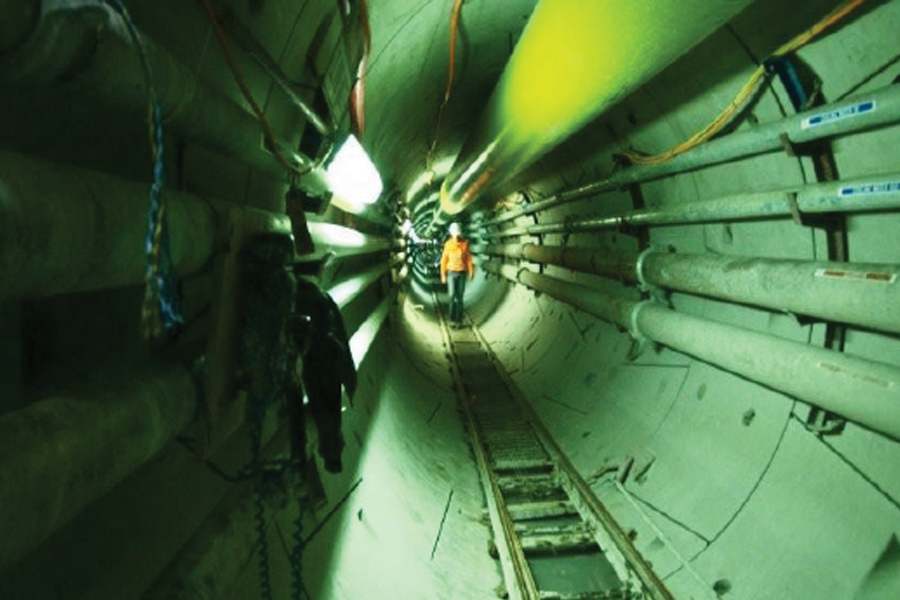

The design is for twin water tunnels with a 2.2km intake and 2km outlet. Each tunnel will be 3.4m in diameter incorporating 6 segment rings 200mm thick. The production of the 21,000 segments was carried out by Precast Concrete at Wacol in Brisbane’s south-west, who were very happy with the improved production rates and reduced labour required to produce the segments with SFRC.

These segments were designed to be reinforced with 35kg/m3 of hooked ends, drawn wire fibres with an aspect ratio of 80. Dramix® RC 80/60-BN premium steel fibres were chosen for the project,not only due to their suitability but also the long term history of the product and the knowledge that the supply could easily be maintained for the full duration of the project.

One of the main drivers for using SFRC in these segments was the requirement for long term durability with a well distributed steel wire fibre creating increased load carrying capacity with significantly enhanced durability in Chloride environments. SFRC was considered to effectively eliminate spalling of the concrete surface, even though fibres located in a thin surface zone can be actively corroding.

The biggest benefit of using SFRC for the segments was the minimum repairs required to the segments after installation. By using SFRC the concrete is completely reinforced with no unreinforced zones that can be prone to damage during handling and installation. A total of 20 minor repairs were required and were only due to the ram shoes from the tunnel boring machine (TBM) not being correctly adjusted, and therefore applying increased point loads to the segments.

Since the start of this project we have now seen two similar projects being constructed in Sydney, the Sydney Desalination Plant at Kurnell, and the City West Cable Tunnel, and they too have chosen to utilise the significant benefits of using SFRC by adopting Dramix steel fibres.